Silafrica is a trusted partner and valued supplier to some of the largest food and beverage brands like Pepsi, Coca-Cola, Diageo, Heineken, Unilever, SAB Miller, AB InBev, Daima, and many more.

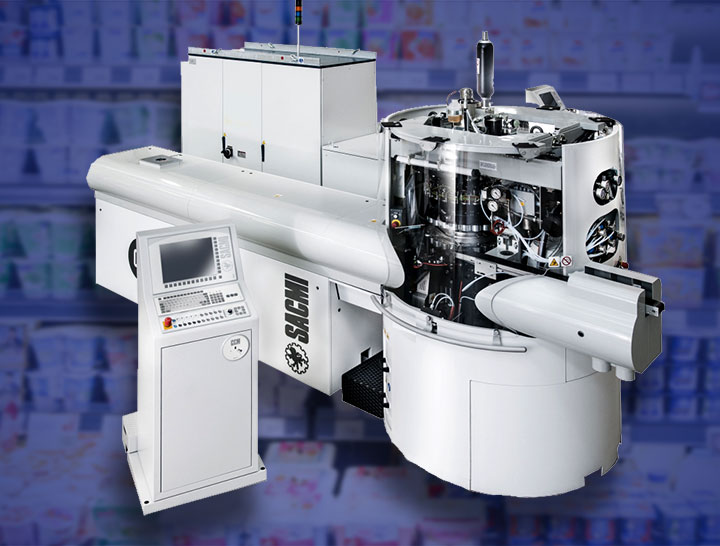

Manufactured by Swiss leader in plastics manufacturing, Nestal, this equipment represents the next generation of efficiency, productivity, speed, and savings. “This latest addition is another example of the world-class line up of technology and supply chain partners we’ve selected,” states Akshay Shah, group managing director of Silafrica. “With the availability of this new Nestal manufacturing platform, our customers now have the opportunity to drive greater sales and market share with packaging that is more cost-effective, sustainable and most importantly, preferred by the consumer.”

ICM brings numerous advantages when compared to older manufacturing techniques. Traditional thermoforming requires considerably more material and consumes more energy in the process resulting associated cost increases in both instances.

Silafrica’s latest-generation ICM also provides the same benefits of traditional injection molding, but with even thinner wall construction that requires less packaging material, weighs less, but still maintains comparable strength and rigidity. In addition, the packaging can be produced with in-mold labeling. Currently available are 100, 150, 250 and 500-gram sizes, making injection compression molding well suited for single-serve, multi-serve or multi-use.

Associated advantages and increased production volume give Silafrica the highest manufacturing capacity in the region. The company currently has five lines dedicated to the production of yogurt packaging, with currently a total of over 200 million units of annual production capacity.

Packaging generated by ICM is cylindrical if shape with a round top and base. This configuration is ideally suited for consumables like pudding, a variety of beverages and yogurt, among other liquid and viscous single and multi-serve foods beverages and condiments. Yogurt brand and long-time client Diama is among five brands that are currently in the process of introducing products via packaging manufactured by new ICM process.

The new equipment is located in Silafrica’s Kenya facility. “Each of our three manufacturing facilities are strategically located throughout East Africa and all are ISO 9001 Certified and FSSC 22000 Certified for food safety and quality standards, as well as Ecovadis rated for sustainability,” adds Shah. “Each facility is equipped with its own water and power supply, and is supported by a highly-trained, regional workforce, giving the global brands we support the supply chain assurance they need.”